Architectural V Grooving for Seamless Metal Bending

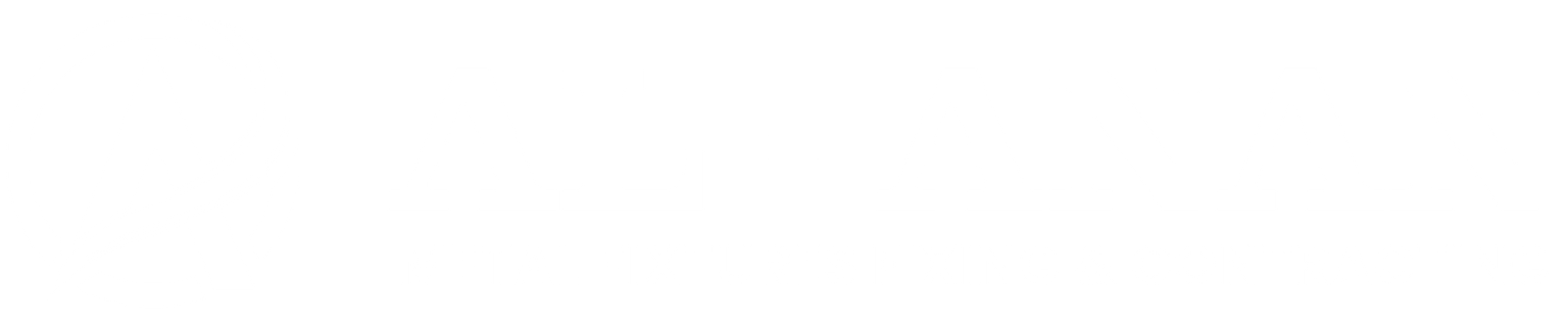

Our CNC-controlled V grooving creates precise angular channels (30°-45°) in stainless steel and aluminum sheets, enabling clean 90° bends without material fatigue. Ideal for decorative cladding, signage, and enclosures, this technique produces crisp edges that eliminate visible welding seams in premium architectural applications.

Al Anan’s proprietary depth-control system maintains consistent groove dimensions across batch productions, ensuring uniform bending for modular installations. We achieve tolerances of ±0.2mm even on brushed and mirror-finished surfaces – preserving aesthetic integrity for luxury interiors and façades.

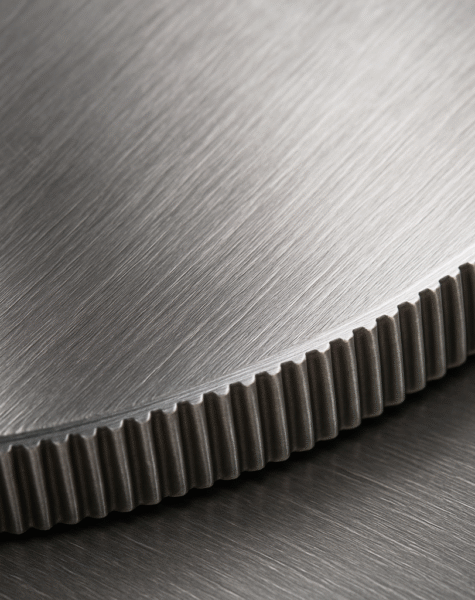

Using CNC-controlled diamond cutters, we achieve V-angle accuracy within ±0.3° at depths calibrated to 90% of material thickness. Our dynamic cooling system prevents work hardening during high-speed grooving.

For architectural panels, we program groove spacing with algorithmic precision to accommodate thermal expansion in UAE's 45°C summers - preventing warping or joint failure.

V-grooved joints retain 95% of material strength versus 70% in welded alternatives. The seamless bends eliminate stress concentration points, extending product lifespan in high-vibration environments.

Our groove geometry allows bend radii down to 1mm - enabling ultra-sharp corners for luxury retail displays and decorative façades impossible with conventional folding.

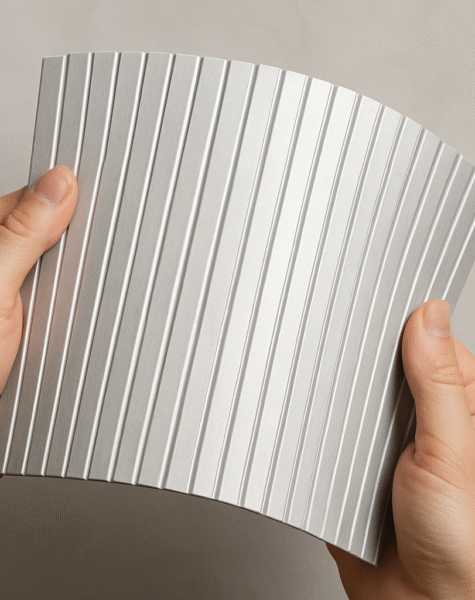

Proprietary non-mar tooling maintains #4 brushed or #8 mirror finishes during grooving. Post-process electropolishing restores grain continuity across bend lines.

We certify Ra <0.2μm surface roughness on critical visible edges, meeting premium architectural specifications for hotels and commercial spaces.

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 529168740, +971 544533336

- alanan786@yahoo.com