Structural U Channel Bending & Fabrication

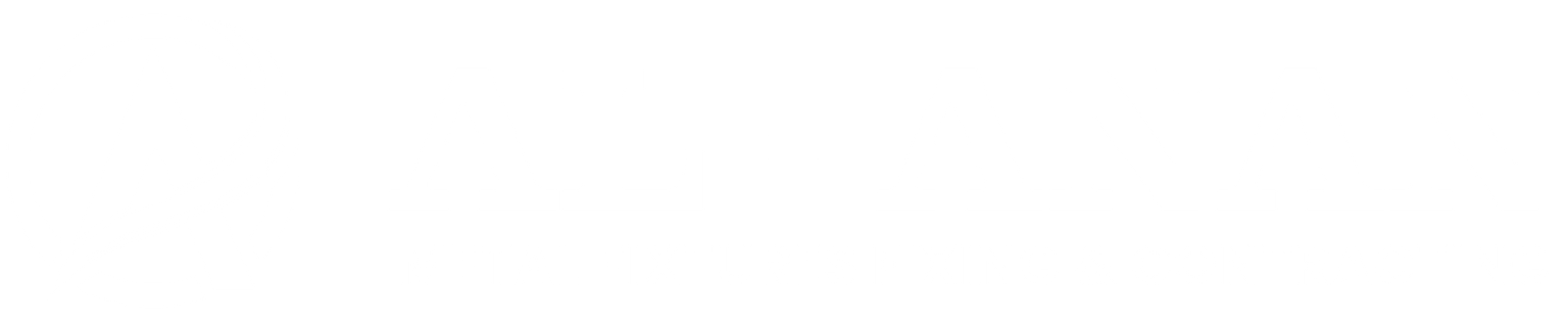

Al Anan fabricates custom U channels for structural and architectural applications using hydraulic press braking and roll forming. We process stainless steel, galvanized steel, and aluminum up to 8m lengths with flange heights from 20mm to 300mm – ideal for HVAC systems, curtain walls, and industrial framing.

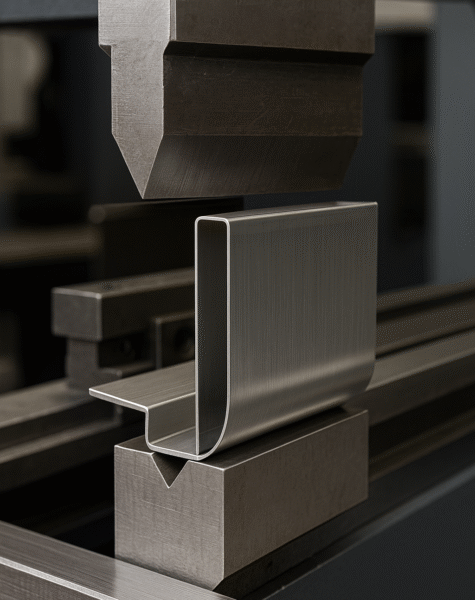

Our in-house tooling shop creates profile-specific dies to achieve consistent angles and radii across large production runs. All U channels undergo laser alignment verification to ensure ±0.5° angular accuracy – critical for load distribution in high-rise buildings and factory installations.

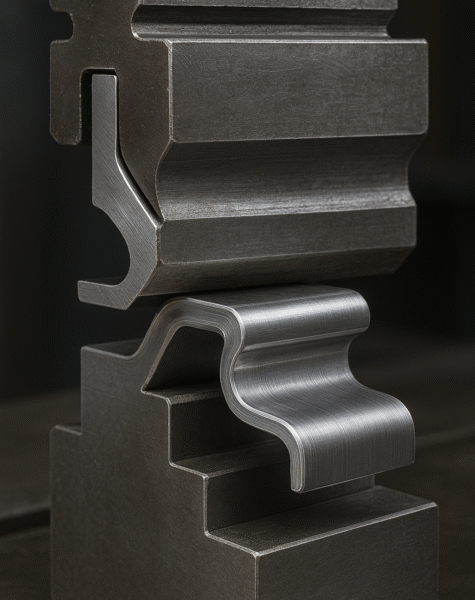

Channel profiles are formed using hydraulic press brakes with CNC-controlled backgauges (±0.1mm positioning). Custom tooling ensures uniform radii across production runs.

For structural applications, we perform stress-relieving heat treatment at 650°C after bending - eliminating internal tensions that cause premature fatigue failure.

Our channels achieve 25% higher load ratings than standard profiles through optimized web-to-flange ratios. Finite element analysis (FEA) validates performance under UAE wind/seismic loads.

Corner-reinforcement techniques prevent buckling at stress points, certified for 50-ton capacities in warehouse racking systems.

Pre-punched bolt patterns with ±0.4mm alignment tolerance reduce on-site assembly time by 60%. Laser-etched positioning marks ensure error-free installations.

We provide custom mounting hardware kits with corrosion-resistant Dacromet® coatings rated for 500-hour salt spray resistance.

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 529168740, +971 544533336

- alanan786@yahoo.com