Heavy-Duty Structural Metal Works

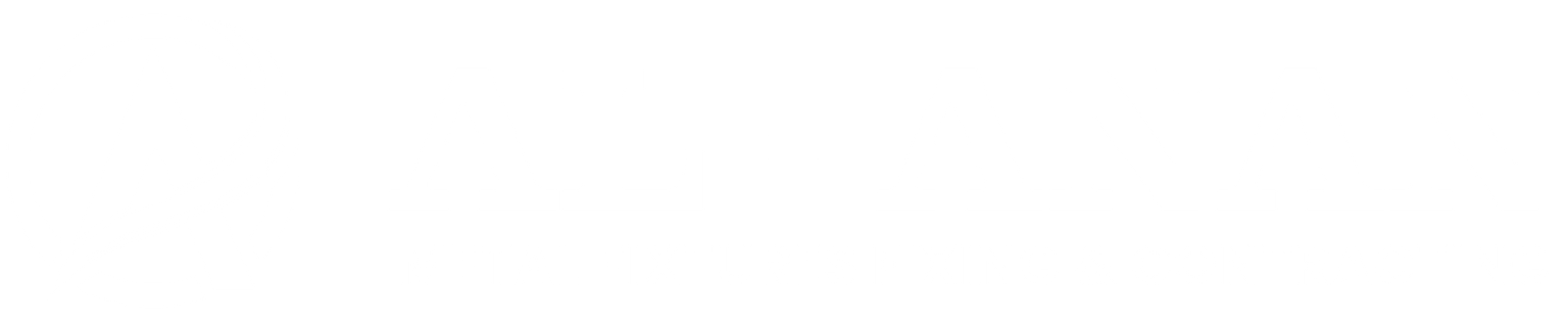

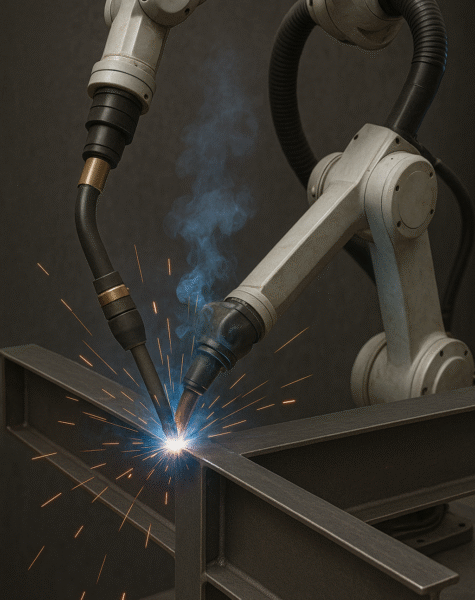

Al Anan engineers industrial-grade structural frameworks for UAE’s construction and manufacturing sectors. Combining robotic welding with manual TIG techniques, we fabricate trusses, platforms, and support systems from carbon/stainless steel with load capacities up to 50 tons. All welds undergo ultrasonic testing for integrity verification.

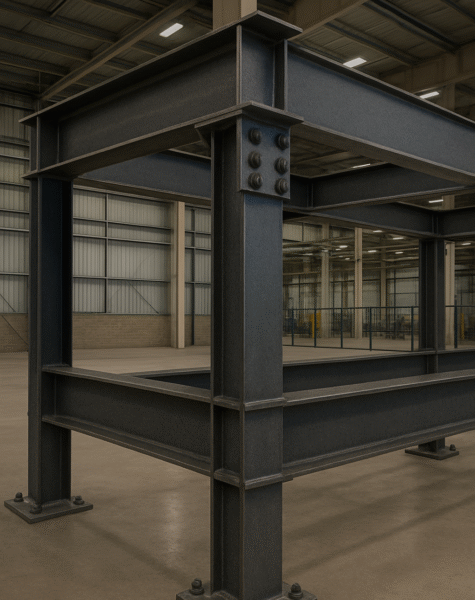

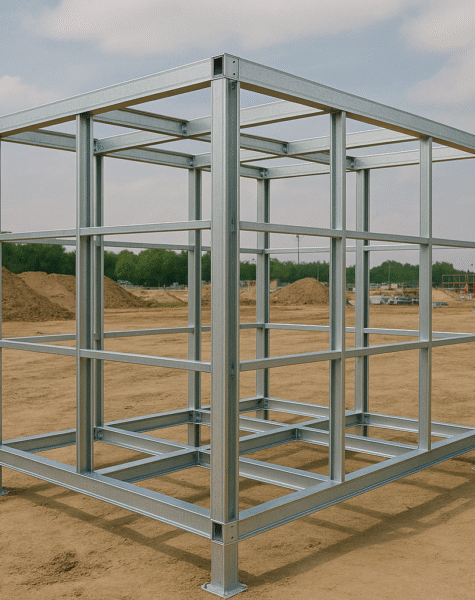

Our project team handles full-cycle solutions from CAD modeling to site installation, including seismic and wind load calculations for UAE building codes. We specialize in modular designs that reduce on-site assembly time by 60% while maintaining ASME Section IX welding standards.

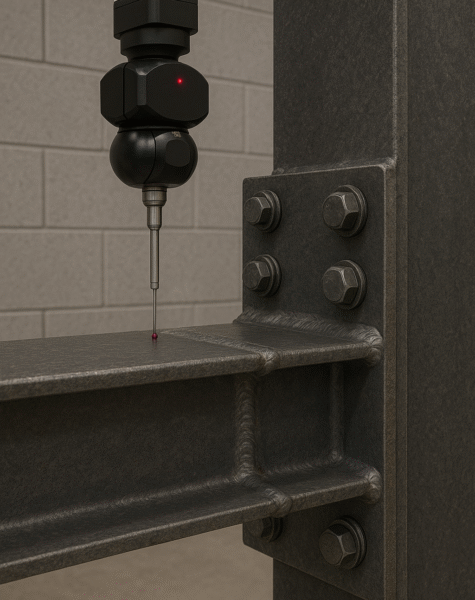

All structural designs undergo FEA simulation for wind/seismic loads per UAE building codes. We laser-cut connection plates with bolt-hole tolerances of ±0.15mm.

Robotic welding cells perform continuous 6G-position welds with UT-tested penetration depth, while minimizing heat distortion in critical joints.

Third-party inspectors verify weld integrity through radiographic testing (RT) and magnetic particle inspection (MPI). We provide EN 1090-2 EXC3 certification packages.

Coordinate-measuring machines (CMM) validate dimensional accuracy within 0.25mm/m across assemblies up to 12m length.

Modular components feature laser-etched alignment marks and proprietary connection systems reducing field labor by 45%.

Our site teams use digital templating for foundation matching, ensuring ±3mm positional accuracy during steel erection.

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 529168740, +971 544533336

- alanan786@yahoo.com